Are you worried about the safety of your plastic water bottle? You want a durable, safe, and reliable bottle, but the market is flooded with cheap options that look good but hide risks.

A quality plastic water bottle, made from materials like BPA-free Tritan or PP, ensures safety by preventing harmful chemical leaching. It also offers better durability against drops and daily use, providing long-term value and peace of mind over cheaper, less reliable alternatives.

Choosing a water bottle seems simple. But as a product developer, you know the details make all the difference. For years, I've worked with brands to navigate the complex world of materials and manufacturing. I've seen firsthand how a small choice in plastic quality can impact brand reputation and customer safety. It’s not just about avoiding the bad stuff; it's about actively choosing the good stuff. Let’s explore what truly separates a great plastic bottle from a potential problem.

How can you tell the quality of a plastic bottle?

Struggling to spot the difference between a premium bottle and a cheap knockoff? You need to ensure the products you source are safe and durable, but visual cues alone can be misleading.

Check the material code, often at the bottom (#5 PP or #7 Tritan are good signs). A quality bottle feels sturdy, has no chemical smell, and boasts a smooth, flawless finish. Always ask the supplier for food-grade safety certification documents.

When I first started, a client wanted the lowest possible price for a new line of sports bottles. They chose a factory that cut corners on the plastic mix. The initial samples looked fine, but after a few months, we received complaints about cracking and a strong plastic taste. This experience taught me a valuable lesson: you have to look beyond the price tag. The best way to judge quality is to use a multi-faceted approach.

Breaking Down Quality Indicators

A truly high-quality plastic bottle's value is in its material science and manufacturing precision. It’s not just one thing, but a combination of factors.

- Material Identification: The small number inside the recycling symbol is your first clue. For reusable bottles, I always recommend sticking to #5 (Polypropylene) and #7 (specifically Tritan, not all #7 plastics are equal). These are known for their stability and safety.

- Physical Inspection: Hold the bottle. Does it feel flimsy or solid? Squeeze it gently. A quality bottle won't deform easily. Look at the seams and edges. They should be smooth, with no rough spots or "flashing," which is excess plastic left over from a poor molding process.

- The Smell Test: Open the bottle and take a sniff. It should be completely neutral. Any chemical or "plasticky" odor is a major red flag, indicating volatile compounds might be present.

- Supplier Verification: Never take a supplier's word for it. Always request copies of their certifications, such as FDA or LFGB compliance. A reputable manufacturer will provide these documents without hesitation.

I've created a simple table to help my clients quickly assess potential products.

| Feature | High-Quality Bottle | Low-Quality Bottle |

|---|---|---|

| Material | Tritan, PP (#5). Clearly marked and BPA-Free. | Unmarked, or low-grade PET (#1) for reusables. |

| Feel & Finish | Sturdy, smooth seams, brilliant clarity. | Flimsy, rough edges, cloudy or inconsistent color. |

| Smell | Neutral, no odor. | Noticeable chemical or plastic smell. |

| Documents | Readily available FDA/LFGB safety certifications. | Hesitant or unable to provide safety documentation. |

By using this checklist, you can move beyond surface-level looks and make an informed decision that protects your brand and your customers.

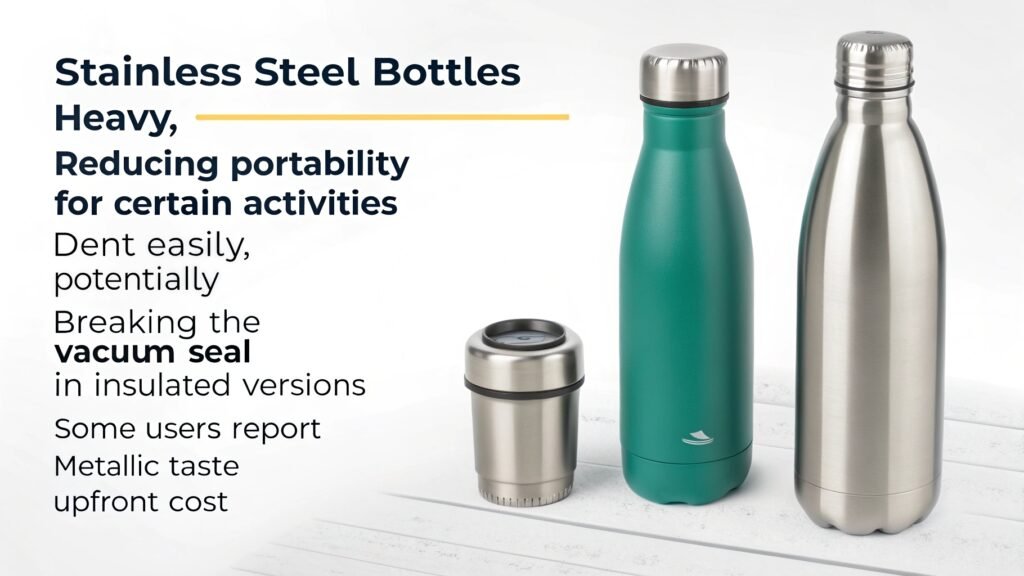

What are the disadvantages of stainless steel water bottles?

Love the eco-friendly appeal of stainless steel but find it impractical sometimes? Many users complain about its weight, tendency to dent, and that occasional metallic taste, making you question its superiority.

The main drawbacks of stainless steel bottles are their weight, making them less portable for some activities. They can dent easily, which can break the vacuum seal in insulated versions, and some users notice a metallic taste. They also cost more upfront.

Stainless steel has a fantastic reputation, and for good reason. It's durable and endlessly recyclable. However, in my work helping brands develop complete drinkware lines, I always advise them not to put all their eggs in one basket. Plastic has its own unique advantages. For example, a brand focusing on ultralight hiking gear found that their customers overwhelmingly preferred lightweight Tritan bottles over heavier steel alternatives. It’s about matching the material to the user’s specific needs. Stainless steel is a great option, but it isn't the perfect solution for every single person or situation.

A Practical Look at Steel's Downsides

While stainless steel is often seen as the gold standard, it’s important to acknowledge its practical limitations, especially when developing a product line for a diverse audience.

- Weight and Portability: The most common complaint is the weight. A standard insulated stainless steel bottle can be two to three times heavier than a comparable plastic one. For athletes, kids, or anyone trying to minimize pack weight, this is a significant factor.

- Durability vs. Aesthetics: Steel is strong, but it's not immune to damage. A single drop can cause a noticeable dent. For insulated bottles, a significant dent can compromise the vacuum layer between the inner and outer walls, rendering the insulation useless. The bottle still holds water, but it loses its main feature.

- Taste and Purity: Most high-quality bottles use 18/8 food-grade stainless steel to prevent flavor transfer. However, some people are very sensitive and can still detect a slight metallic taste. This is more common with lower-grade steel or if acidic drinks like citrus juice are left in the bottle for extended periods.

- Cost Considerations: From a manufacturing and retail perspective, stainless steel is more expensive. The raw material costs more, and the process of shaping, welding, and creating the vacuum insulation is more complex and costly than injection-molding plastic. This higher production cost translates directly to a higher price for the consumer.

For product developers like Emily, understanding these trade-offs is key. Offering both high-quality plastic and stainless steel options allows a brand to cater to different priorities, from the lightweight-focused hiker to the office worker who values insulation above all else.

Do all plastic bottles release microplastics?

The thought of microplastics is unsettling. You read headlines and wonder if every sip from a plastic bottle is unsafe, making it hard to trust any plastic product, even those labeled "BPA-free."

No, not all plastic bottles release microplastics equally. High-quality, stable plastics like Tritan are designed to be highly resistant to degradation. Release is primarily triggered by stress like high heat, UV light, and physical damage, not normal, intended use.

This is a topic I discuss with clients almost every week. There's a lot of fear, and it's my job to separate the science from the scare stories. The key takeaway is that material stability matters. I always explain it like this: think of a rock and a piece of sandstone. Both are stone, but one will crumble under pressure while the other remains solid. It's the same with plastics. Low-quality, single-use plastics are not designed for longevity and can break down more easily. But the materials we use for premium reusable bottles are engineered specifically to avoid this.

Understanding the Nuances of Microplastic Shedding

The conversation around microplastics often lacks nuance. It's not a simple yes-or-no issue. The type of plastic and how you use it are the most important factors.

- Material Makes the Difference: The primary concern for microplastic shedding comes from low-grade or single-use plastics like PET (#1) when they are misused. For instance, reusing a disposable water bottle for months, especially if it's exposed to heat or sun, causes the material to break down. In contrast, materials like Tritan copolyester are specifically engineered for repeated use. They have a much stronger and more stable molecular structure that resists breaking down into smaller particles under normal conditions.

- Usage Conditions are Crucial: The main triggers for microplastic release are stress factors.

- Heat: Putting boiling liquids into a bottle not rated for high temperatures can warp the plastic and degrade its structure. This is why it is essential to check the manufacturer's temperature guidelines.

- UV Radiation: Leaving a plastic bottle in direct sunlight for long periods, like on a car dashboard, can weaken the plastic over time.

- Physical Damage: Deep scratches or cracks create more surface area and weak points where tiny particles could potentially break off.

- The Role of Quality Manufacturing: A well-made bottle has a smooth interior surface. Poor manufacturing can result in microscopic imperfections on the surface, which could be more prone to shedding. This is another reason why I always vet my suppliers' production quality so carefully.

So, while it's technically possible for any plastic to shed particles under extreme stress, a high-quality reusable bottle used as intended poses a minimal risk. The focus should be on choosing bottles made from stable, food-grade materials and caring for them properly—avoiding the dishwasher if not recommended and keeping them out of extreme heat.

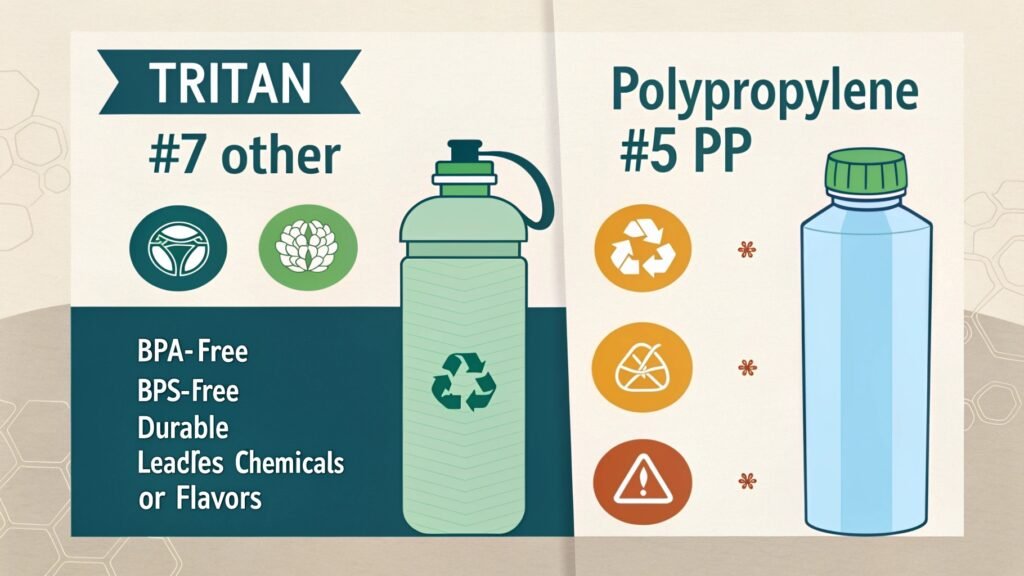

What's the safest plastic for a reusable water bottle?

With so many "BPA-free" labels, how do you know which plastic is truly the safest choice? You need a dependable material that guarantees safety and durability for your customers, not just a marketing claim.

Tritan (#7 Other) is widely considered one of the safest and best materials for reusable water bottles. It's BPA-free, BPS-free, durable, and doesn't leach chemicals or flavors. Polypropylene (#5 PP) is another excellent and safe option, often used for lids.

I've built my reputation on recommending materials I trust completely. For me, Tritan is the top choice for clear, durable water bottles. I remember a partner brand was developing a new line for children. Safety was their number one priority. We chose Tritan not only because it's free of bisphenols (like BPA and BPS), but also because it is shatter-resistant. It provides the glass-like clarity parents like without the safety hazards of actual glass. For opaque bottles or lids, Polypropylene (PP) is my go-to. It's a time-tested, stable, and cost-effective material that is excellent for food contact.

Comparing the Top Safe Plastics

When we talk about "safe," we are looking for a material that is stable, non-leaching, and durable enough for repeated use. Let's break down the best options available for high-quality reusable drinkware.

- Tritan Copolyester (#7): This is the modern champion of reusable plastic bottles.

- Safety: It is completely free of BPA, BPS, and any other bisphenols. It has undergone extensive third-party testing to ensure it doesn't leach any harmful substances.

- Durability: It has exceptional impact and shatter resistance, far superior to other clear plastics.

- Clarity & Aesthetics: Tritan offers beautiful, glass-like clarity that doesn't stain or retain odors. It's also easy to mold into innovative shapes and add vibrant colors.

- Polypropylene (#5 PP): This is a workhorse material in the food and drinkware industry.

- Safety: PP has a long history of safe use in food containers (think yogurt cups and medicine bottles). It's a very stable polymer and is BPA-free.

- Properties: It’s more flexible and softer than Tritan, making it ideal for lids that need a tight seal. It is typically opaque or translucent and is very cost-effective.

- Heat Resistance: It has a high melting point, so it is generally dishwasher-safe (top rack).

To make it easier, here is a direct comparison for product development purposes:

| Feature | Tritan | Polypropylene (PP) |

|---|---|---|

| Primary Use | Bottle Body | Lids, Opaque Bottle Bodies |

| Clarity | Excellent, glass-like | Opaque or Translucent |

| BPA/BPS Free | Yes | Yes |

| Impact Resistance | Very High | Medium (Flexible) |

| Dishwasher Safe | Yes (check manufacturer guidelines) | Yes (usually top-rack only) |

| Cost | Premium | Economical |

For any brand I work with, the choice often comes down to this: if you want a premium, clear, and virtually unbreakable bottle, choose Tritan. If you need a reliable, cost-effective, and safe material, especially for opaque designs and functional lids, Polypropylene is an excellent choice.

Conclusion

Ultimately, choosing a quality plastic bottle made from materials like Tritan or PP is a smart investment in safety, durability, and peace of mind for you and your customers.